This makes Mandrel testing critical to ensuring long-term performance of PVC sewer lines. Mandrel Design. Thuro Inc. manufactures mandrel sets for use in The City of Calgary. Each set has a proving ring with unique serial number that is approved for use from the City of Calgary Water Resources department.

We offer various High Speed Mandrels to satisfy all laboratory needs. Here are the following mandrels we provide: A: Mandrel, Corkscrew 3/32" Shank B: Tapered Handpiece Mandrel C: Mandrel 3/32" Shank, 1/16" Screw 8mm large head D: Mandrel, Heavy Duty. 1/8" Shank, 1/16" Screw E: Mandrel, Spiral 3/32" Shank F: Mandrel, Spiral w/Hex Nut 3/32" Shank G: Mandrel, Heavy Duty 1/8" Shank, 1/8" Screw H

Stainless Steel Lab Mandrel from Premier Dental. These gold-color heads are made of specially formulated aluminum bronze alloy which results in minimal wear on the threads, resists rusting and lasts up to six times longer than conventional steel mandrels.The shafts are made of tough stainless steel and do not bend.

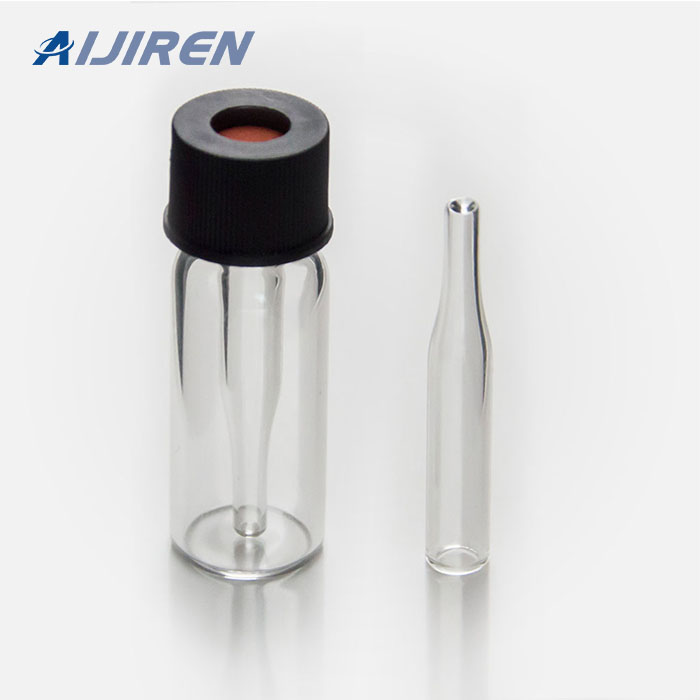

National Scientific Polypropylene Mandrel Interior Conical Base Inserts, Insert Diameter 6mm, 250µL Volume (Case of 1000) Currently unavailable. We don't know when or if this item will be back in stock.

Cities, counties and states use a mandrel to inspect the inside of underground pines and sewer conduits, generally after new construction or during maintenance. Independent pipeline inspection companies complete the tests.

A generally cylindrical cutting insert is provided for removable and replaceable affixation between the upper and lower mandrel elements. The cutting insert includes a cutting slot that is defined entirely by the insert so that the upper and lower elements are located in positions where damage from the cutting knife can be minimized.

A mandrel for use in a crosshead extrusion process for manufacturing hose. The mandrel includes a core composed of a high tensile strength material; a tie layer disposed around and adhering to the core and an elongated cylindrical body disposed around the tie layer.

Many use a mandrel-wiper chart (see Figure 2), which is a convenient way to convey information derived from mathematical formulas and rules of thumb. The typical mandrel-wiper chart displays the recommendations by wall factor versus D of bend. The wall factor is the tube or pipe"s OD divided by the wall thickness.

Standard Abrasives™ Cartridge Roll Mandrels is a tool attachment that holds an abrasive cartridge roll (sold separately). Together, the mandrel and cartridge roll grind and finish hard-to-reach areas of a workpiece, such as angles and curves.

The use of dimensionless factors to describe gear tooth geometry seems to have a strong appeal to gear engineers. The stress factors I and J, for instance, are well established in AGMA literature. The use of the rack shift coefficient "x" to describe nonstandard gear proportions is common in Europe, but is not as commonly used in the United States.

With use of our products, one can achieve high precision clamping & control runout & perpendicularity parameters consistently. This Turning & Boring Collets can be used for auto components manufacturing on conventional SPM & CNC machines and is useful for gears, flanges, liners, bushes & housings like components.

Comments . Transcription . Journal 2301 - Patents Office

There are several types of arbors for lathes. Expanding mandrels are slightly tapered and have an expandable wedge for holding the workpiece. Lathes also use mandrels that are set in the center and turned with lathe dogs. In addition to lathes, arbors are used to hold buffing wheels, circular saws, and sanding discs.

Rotary Draw Mandrel Bending 1) The tube must be supported on all surfaces, ID and OD at tangent during bending. Mandrel supports tube on the ID Bend Die supports tube on inside radius of tube OD and provides the radius forming size During bending, the tube is drawn over the mandrel while being supported on all sides. This process induces high

REFERENCE: 2010 Standard Specifications Section 715.09 2009 Interim GIFE Section 4.11.2 CONSTRUCTION MEMORANDUM 09-20 The purpose of this memo is to clarify the requirements for mandrel testing of thermoplastic pipe. Section 715 of the Standard Specifications requires contractors to perform a pass or fail mandrel test on