D522 / D522M-17 Standard Test Methods for Mandrel Bend Test of Attached Organic Coatings flexibility~ mandrel bend test~ cylindrical mandrel apparatus~ organic coatings~ cracking resistance~ rubber~

Standard with four wrench flats on mandrel bodies for easier installation to the machine. Dozens of mandrel thread specifications (both inch and metric) are standard at no extra cost. Long-life nickel-aluminum-bronze* nose inserts and mandrel balls for bending high-carbon steel, stainless steel, titanium, and nickel alloy tubing.

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Mandrel Placement. Proper placement of the mandrel is critical. The front end of the mandrel shank should be set just past tangent. Bending off the mandrel balls causes the bend quality to suffer. The balls do not support the tube—that's what the shank is designed for. Figure 1 gives tangent settings for a standard mandrel.

Rotary Draw Mandrel Bending 1) The tube must be supported on all surfaces, ID and OD at tangent during bending. Mandrel supports tube on the ID Bend Die supports tube on inside radius of tube OD and provides the radius forming size During bending, the tube is drawn over the mandrel while being supported on all sides. This process induces high

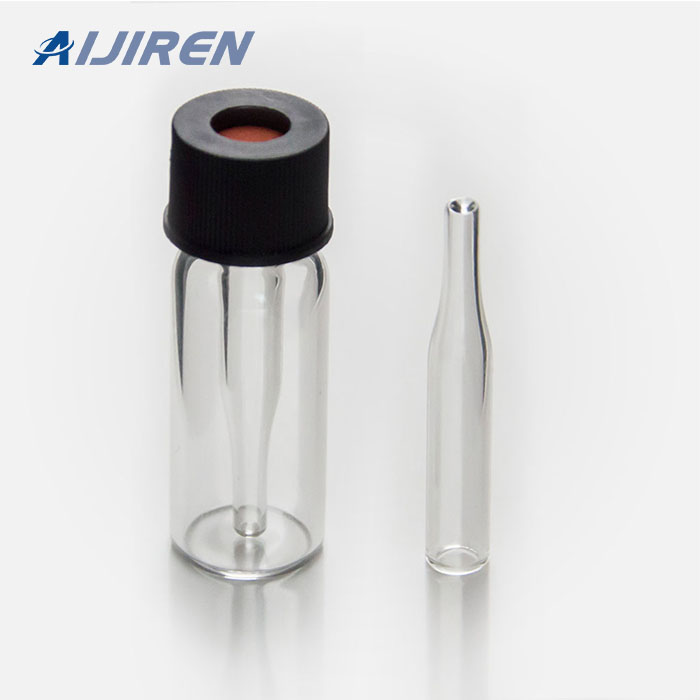

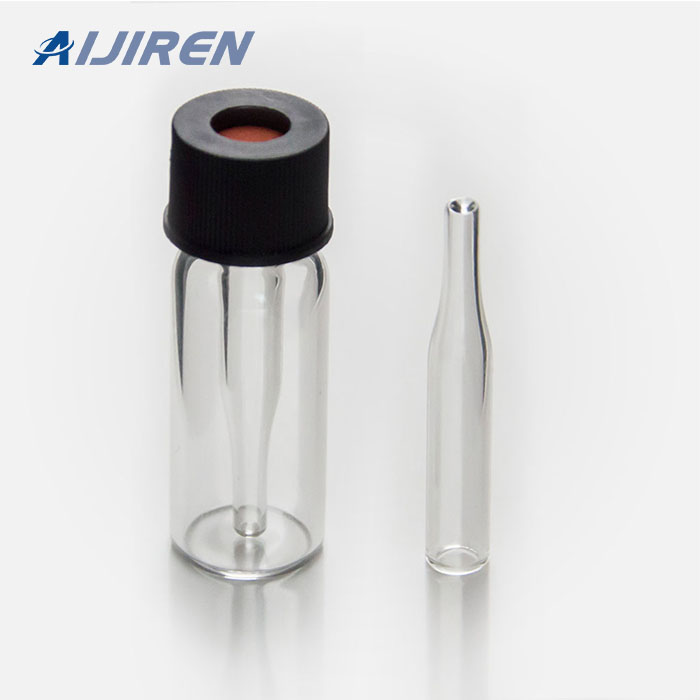

National Scientific Polypropylene Mandrel Interior Conical Base Inserts, Insert Diameter 6mm, 250µL Volume (Case of 1000) Currently unavailable. We don't know when or if this item will be back in stock.

• Insert Installation Tool, Prewinder, Type II, Steel Mandrel , Plastic Prewinder, Thread Type UNF, Use With Internal Thread Size 10-32, For Use With For Use With Free Running and Screw Locking Inserts, General Purpose .

Shop Flexible Mandrel, 4 in. Duct by Greenlee (39257) at Graybar, your trusted resource for Wire and Cable Pulling Tool Accessories and other Greenlee products.

Each mandrel has a Teflon body with two braided steel loop eyes on each end for versatility and strength. It is designed to give an 80% fill, based on size of mandrel chose. Duct mandrel offered are based on highest grade industrial polymers & inputs.

Mandrel Chart on Page 38 D E C A B F 2.95 G 3.31 Dimensions Note – dimensions shown without optional part locator. Perfect Combination – A Royal Quick-Grip™ CNC Collet Chuck on the main spindle and a Royal CNC Expanding Mandrel System on the sub.

Mandrels or arbors are tool components that are used to grip or clamp the material being machined or other moving tool components. Some mandrels are shaped bars of metal that are placed inside or next to the workpiece to be machined. These arbors are used to bend the exhaust pipes for automobiles

Use thread insert tools to install helical threads into a drilled hole or repair a stripped screw or bolt thread. Since a threaded insert is as strong or stronger than the original, it can extend the life of structures and machinery. A mandrel and nosepiece is usually included, and you can purchase additional fittings depending on the project.

Conduit Technologies supplies flexible leather mandrels in standard and custom sizes. Mandrels have approx 1/4" thick leather with 16 guage metal backing discs, steel pipe spacers, and galvanized steel cable with crimped loops on each end.

Versatile ring mandrel helps you size, shape, hammer and straighten rings. Features: • Hardened steel construction • Etched US ring sizes from 1-15 in 1/4 increments

To use (forming a ring using the steel ring mandrel):

• Position the ring shank on the mandrel at the designated ring size.

• Use a rawhide mallet to gently coax the ring shank into the shape of

The Condux 8" Flexible Steel Mandrel has steel discs in graduated sizes with a braided steel cable and a pulling eye on each end for strength and versatility. The graduated discs are ideal for removing obstructions in conduit with extreme bends. When using the flex steel mandrel, there is a potential for duct shaving to occur.