At a process speed of 120 feet per minute, it can print 2000 fullcolor (or 8000 single color) lettersize images (two-up) per hour. With a standard printing resolution of 800 dpi, E-Print’s proprietary image enhancement technology achieves outstanding, crisp, brilliant images, both for text and color graphics.

A generally cylindrical cutting insert is provided for removable and replaceable affixation between the upper and lower mandrel elements. The cutting insert includes a cutting slot that is defined entirely by the insert so that the upper and lower elements are located in positions where damage from the cutting knife can be minimized.

Search 6 million Products. Find materials, components, equipment, MRO supplies and more.

1 day ago · The concepts are shown in Revit 2014, but can be performed on 2013. Showing how to use the calculator makes it even better. 127-339,7 350,000 2010 India Hot Rolling Line: Rolling Equipment (FQM) IN OPERATION –FAC SIGNED 6 TMK O. Line Designation Tables 8. Standard finishes and materials PGregalvanized (i.

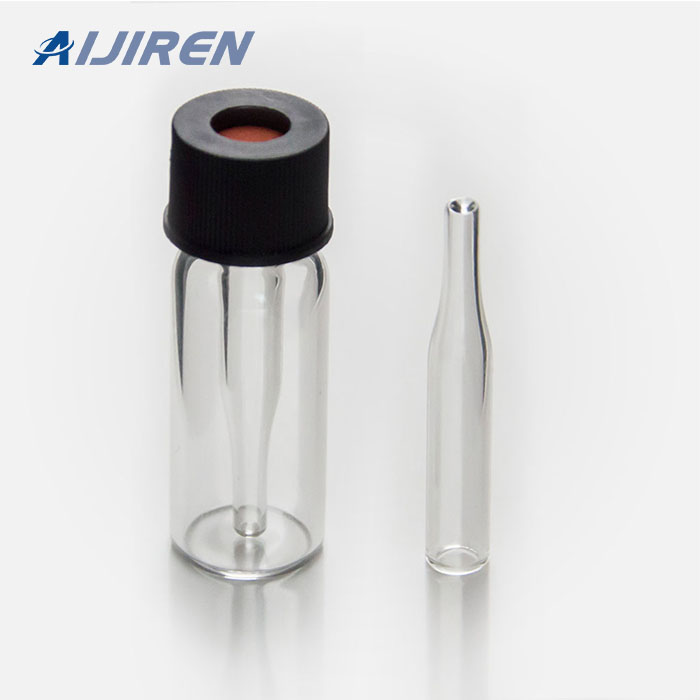

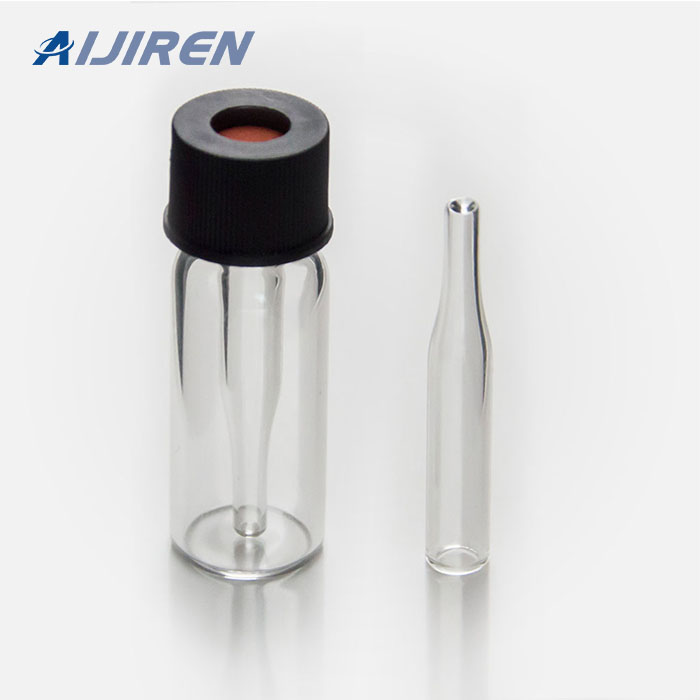

1.5ml Laboratory Sample Crimp Vials Nd11 , Find Complete Details about 1.5ml Laboratory Sample Crimp Vials Nd11,Sample Crimp Vials Nd11,Sample Crimp Vials Nd11,Sample Crimp Vials Nd11 from Laboratory Bottle Supplier or Manufacturer-Zhejiang Aijiren Technology Inc.

Polymer matrix composites of 70%LDPE +10% TiO 2 +20% Al 2 O 3 composition is biocompatible and a good candidate for biomaterial. Thus based on the inference of this study the above polymer matrix composite is suitable for orthopaedic applications and can be applied on hard and soft tissues of implantable materials in a human body.

0.3ml PP Snap Ring Micro-Vial, Clear(id:9097060). View product details of 0.3ml PP Snap Ring Micro-Vial, Clear from Zhejiang Aijiren Technology Co.,Ltd manufacturer in EC21

Polymer Standards and Reference Materials PSS is one of the world's largest manufacturers of aqueous and organic reference polymers, specialty polymers , and customer-designed polymers. A great selection of polymer types in a wide range of molar masses is produced regularly.

The use of a MTV will be subject to the requirements stated in Article 1.07.05- Load Restrictions. The Engineer may limit the use of the vehicle if it is determined that the use of the MTV may damage highway components, utilities, or bridges. The Contractor shall submit to the Engineer at time of pre-construction the following information:

Dec 15, 2012 · Our high production lines manufacture acetal mandrel for use in the manufacture of tight-tolerance tubes (tolerance as tight as 0.0005"). We have bump or taper tubing for variable OD's and ID's. Finally, we provide some secondary operations, e.g. precise cutting, tipping, flaring, welding, and some other subassemblies such as angiographic

Micro Insert & Shell Vials V18A IB300 IPA 150 Specifications Model No. 150 IPB250 IPB250-P IA250 IB300 V18A Size 29*5mm 29*5.7mm 29*5.7mm 31 "5mm 31 *6mm 8.2*40mm Description 150ul Insert with mandrel interior and polymer feet, suits for ND8 Vials 250ul Insert with mandrel interior and polymer feet, suits for ND9 Vials

Sufficiently open the apparatus to insert the mandrel with the correct diameter turning the handle of the pressure rollers anti clockwise. Place and secure a test-panel in the apparatus, positioned against the mandrel. Fix it upright into the clamp. Pull the handle, and with a smooth movement, taking 1 - 2 seconds, make an even 180° bend.

The massof coating in such cases shall be as follows: Grade of Minimum Average Coating Minimum Coating Coating Triple Spot Test Single Spot Test g/rrr' g/rrr' (1) (2) (3) 100 100 90 80 80 75 NOTE - For the abovegradeofcoating, the mandrel diameter for bendtest. 2, Kharadi, Haveli Pune - 411014 Maharashtra, INDIA +91 20 6719 4200.

1.5ml wide opening crimp-top vial with write-on spot , clear 11.6*32mm borosilicate type 7 250uL Insert with mandrel interior and polymer feet, 29*5.7mm, for 9mm ...

A lathe (/ l eɪ ð /) is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.