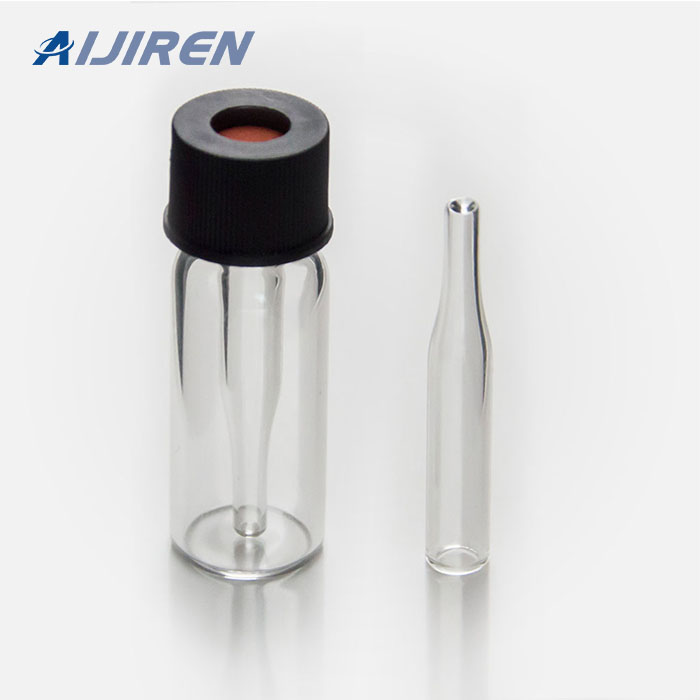

Micro-Inserts & Shell Vials & Racks &Crimper 100pcs/pack. IP150. 150ul Insert with mandrel interior and polymer feet, 29*5mm; suits for ND8 Vials. IP250. 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9 Vials. I200. 200ul Micro-Insert,31*5mm,clear glass,flat bottom; suits for ND8 Vials. I300

Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com.The firm provides professional HOME INSPECTION SERVICES and also extensive HOME INSPECTION EDUCATION and home inspection-related PUBLICATIONS.

Since 1875, Shimadzu is pursuing leading-edge science and technologies in analytical and measuring instruments including chromatographs and mass spectrometers, medical devices, aeronautics, and industrial equipment.

S6.2.3 At the beginning of each performance test in the test sequence (S7,3, S7.5, S7.7 through S7.11, and S7.13 through S7.19 of this standard), unless otherwise specified, each propulsion battery of an EV is at the maximum state of charge recommended by the manufacturer, as stated in the vehicle operator's manual or on a label that is

Your best source for high quality & innovative woodworking tools, finishing supplies, hardware, lumber & know-how. Find everything you need to make your next project a success.

Standard with four wrench flats on mandrel bodies for easier installation to the machine. Dozens of mandrel thread specifications (both inch and metric) are standard at no extra cost. Long-life nickel-aluminum-bronze* nose inserts and mandrel balls for bending high-carbon steel, stainless steel, titanium, and nickel alloy tubing.

These Flat Bottom Glass Inserts are designed to be used in 2mL standard opening crimp top and screw thread vials. They represent an economical alternative to the conical limited volume inserts. The 250µL Glass Flat Bottom Inserts make an excellent choice to daily chromatographic experiments in the lab coining the highest quality and consistent

Quzhou Lab Technology Co.,Ltd,hplc vials manufacturer . Micro-Inserts & Shell Vials & Racks &Crimper 100pcs/pack IP150 150ul Insert with mandrel interior and polymer feet, 29*5mm; suits for ND8 Vials IP250 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9 Vials I200 200ul Micro-Insert,31

Catch basin storm drains from NDS. Superior quality stormwater residential and commercial drainage systems. Choose from 6 to 24" catch basin drain systems.

Wire Brush Mandrel Flat steel bristles with a pulling eye on one end and a loop on the other end. Easily removes sand, grit and other light obstructions from the duct. 800 lbs. (3,558 N) load

The invention provides a method of making an elastomeric mandrel for use in formation of parts from composite materials. The method of making includes providing a separable mold with an interior chamber shaped to provide a desired exterior mandrel size and shape; applying uncured elastomeric material to surfaces of the interior chamber of separated parts of the mold; joining the elastomeric

machines, mandrel benders, NC swaging equipment and metalforming machinery. Ercolina’s experienced sales, service and support staff is always ready to offer positive application solutions for today’s fabricator. Company Profile: CML USA, Inc. consistently leads the industry providing

Wide Opening 150ul insert price Aijiren Australia Inserts & Shell Vials,high performance liquid Micro-Inserts & Shell Vials & Racks &Crimper 100pcs/pack IP150 150ul Insert with mandrel interior and polymer feet, 29*5mm; suits for ND8 Vials IP250 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9 Vials I200 200ul Micro

There are 3 types of micro-insert, 29*5mm 150uL micro-insert with mandrel interior&polymer feet, 150uL conical bottom micro-insert and 250uL flat bottom micro-insert. Quote Now Laboratory Bottles Manufacturers & Suppliers -

s = unit compressive stress in the ring (pounds per square foot) H = depth of manhole, feet Using an allowable concrete stress of 45% of the minimum specified compressive strength of 4,000 psi, the allowable compressive stress would be 1,800 psi. Substituting this value for s yields the following: = 3.4 s H 1,800 = 3.4H then H = 530 feet