Cities, counties and states use a mandrel to inspect the inside of underground pines and sewer conduits, generally after new construction or during maintenance. Independent pipeline inspection companies complete the tests.

Mandrel. Use this to make pens, pencil, and other small turned projects. 5.0 out of 5 stars by Reyo1911 on 03\01\2013. must have. this item is a must have. 4.0 out of

Apr 16, 2019 · Polymer mandrels also have been used for the manufacturing of independent components for braid reinforced catheter shafts, such as thin-walled polymer tubes and stainless steel braided tubes. These components are manually assembled and thermally fused to provide complex constructions with discrete properties along the catheter shaft.

Use thread insert tools to install helical threads into a drilled hole or repair a stripped screw or bolt thread. Since a threaded insert is as strong or stronger than the original, it can extend the life of structures and machinery. A mandrel and nosepiece is usually included, and you can purchase additional fittings depending on the project.

Jun 28, 2006 · We used to make expandable arbors for second operation work in the aircraft industry. chuck or collet on the turned shank, rough turn an indicating ares for future use, rough turn the diameter, split 4 to six places, releave a groove behind the shoulder about .100 to a fairly deep depth to allow for a little flex, rechuck drill and bore the I.d. and tape, form a 15 degree taper on the i.d

Choose from our selection of expanding mandrels, including expanding-end lathe mandrels, wide-diameter range lathe mandrels, and more. In stock and ready to ship.

Mandrel Placement. Proper placement of the mandrel is critical. The front end of the mandrel shank should be set just past tangent. Bending off the mandrel balls causes the bend quality to suffer. The balls do not support the tube—that's what the shank is designed for. Figure 1 gives tangent settings for a standard mandrel.

Rotary Draw Mandrel Bending 1) The tube must be supported on all surfaces, ID and OD at tangent during bending. Mandrel supports tube on the ID Bend Die supports tube on inside radius of tube OD and provides the radius forming size During bending, the tube is drawn over the mandrel while being supported on all sides. This process induces high

I' m sure I will use it on another project and it is made well. I was really looking for the same product in a 6mm thread. I make several products on the lathe that require an insert with a 6mm thread. I use a 6mm bolt with a couple of nuts in the middle and the head removed. I use it as a mandrel in my chuck on the lathe.

REFERENCE: 2010 Standard Specifications Section 715.09 2009 Interim GIFE Section 4.11.2 CONSTRUCTION MEMORANDUM 09-20 The purpose of this memo is to clarify the requirements for mandrel testing of thermoplastic pipe. Section 715 of the Standard Specifications requires contractors to perform a pass or fail mandrel test on

A ring mandrel can have grooved ring sizes marked on it to assist with sizing rings. Rio Grande has extremely well-made, marked mandrels. An unmarked ring mandrel is a good choice if you want the mandrel to assist with shaping wires for earrings or bending metal for rings. Keep the marked mandrel simply for sizing rings.

A generally cylindrical cutting insert is provided for removable and replaceable affixation between the upper and lower mandrel elements. The cutting insert includes a cutting slot that is defined entirely by the insert so that the upper and lower elements are located in positions where damage from the cutting knife can be minimized.

The brass compression fitting allows you to turn shorter length blanks without having to use a wood spacer. Simply slide the fitting onto the shaft and tighten it at the correct location for your blank. This Pro Pen Turning Mandrel includes a #2 morse taper arbor for use with a #2 morse taper lathe, a 7mm mandrel shaft and knurled nut.

Conduit Technologies supplies flexible and solid standard and customized mandrels to the underground utilities industry. 1.25" solid aluminum mandrel for Sch 80 ...

standard expanding mandrel sleeves The standard length sleeves & flush type sleeves can be used with all types of mandrels, & are interchangeable within the diameter range of each type. Sleeves can be supplied bonded, to keep swarf away from the double angle form, to help prolong the sleeves life and accuracy.

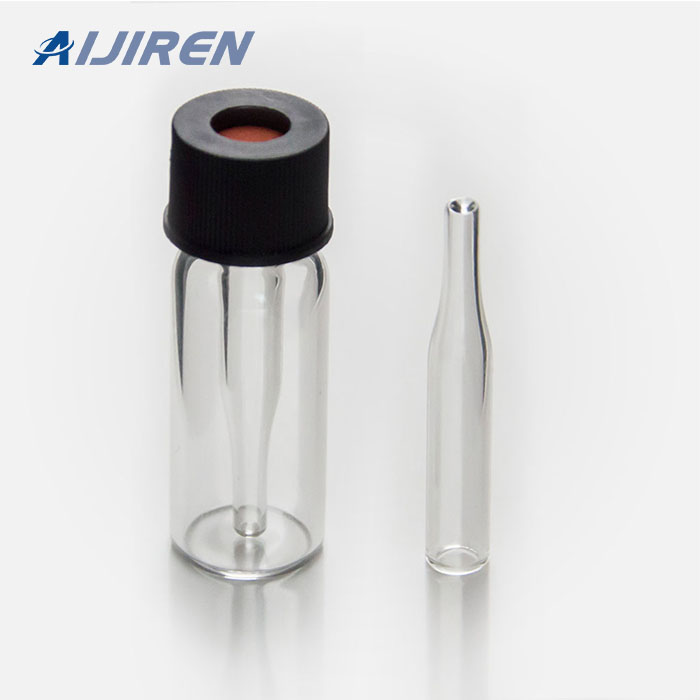

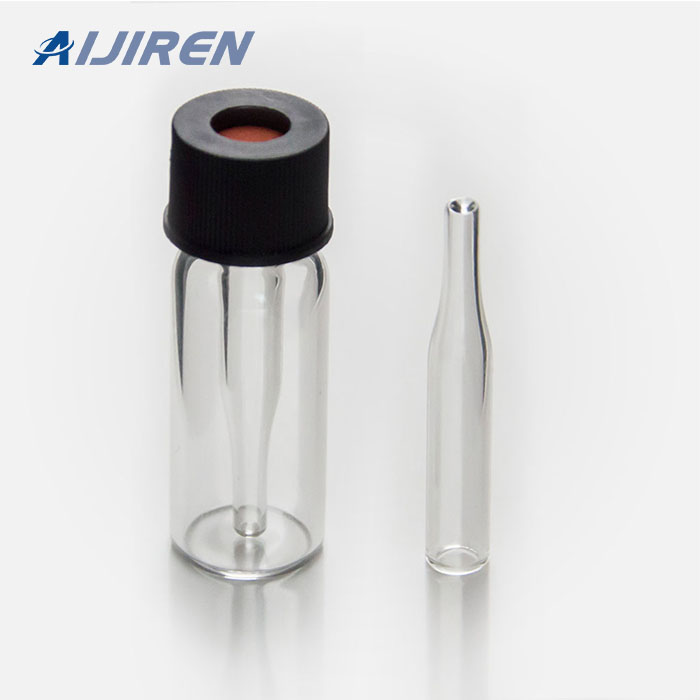

National Scientific Polypropylene Mandrel Interior Conical Base Inserts, Insert Diameter 6mm, 250µL Volume (Case of 1000) Currently unavailable. We don't know when or if this item will be back in stock.

Mandrel Placement. Proper placement of the mandrel is critical. The front end of the mandrel shank should be set just past tangent. Bending off the mandrel balls causes the bend quality to suffer. The balls do not support the tube—that's what the shank is designed for. Figure 1 gives tangent settings for a standard mandrel.

Apr 16, 2019 · Polymer mandrels also have been used for the manufacturing of independent components for braid reinforced catheter shafts, such as thin-walled polymer tubes and stainless steel braided tubes. These components are manually assembled and thermally fused to provide complex constructions with discrete properties along the catheter shaft.

Standard with four wrench flats on mandrel bodies for easier installation to the machine. Dozens of mandrel thread specifications (both inch and metric) are standard at no extra cost. Long-life nickel-aluminum-bronze* nose inserts and mandrel balls for bending high-carbon steel, stainless steel, titanium, and nickel alloy tubing.

Cities, counties and states use a mandrel to inspect the inside of underground pines and sewer conduits, generally after new construction or during maintenance. Independent pipeline inspection companies complete the tests.

Choose from our selection of expanding mandrels, including expanding-end lathe mandrels, wide-diameter range lathe mandrels, and more. In stock and ready to ship.

Rotary Draw Mandrel Bending 1) The tube must be supported on all surfaces, ID and OD at tangent during bending. Mandrel supports tube on the ID Bend Die supports tube on inside radius of tube OD and provides the radius forming size During bending, the tube is drawn over the mandrel while being supported on all sides. This process induces high

Conduit Technologies supplies flexible and solid standard and customized mandrels to the underground utilities industry. 1.25" solid aluminum mandrel for Sch 80 ...

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and determine the applicability of regulatory limitations prior to use.

lugs for use in dual-string installations. The exterior ported lug on the BR & CR deflector lug mandrels is located near the middle of the mandrel and is called a capsule lug. The subsurface control device is installed into the top of the capsule lug, and the reverse flow check valve is installed into the bottom of the capsule lug.